Quaternary Disinfectants are broad spectrum disinfectants. According to EPA’s definition broad spectrum disinfectants show efficacy against all the three major classes of microbial organisms-Bacteria, Fungi and Viruses

Cleaning products used in houses, industries, public places are mainly based on quaternary ammonium compounds.

The risk of contamination is increasing at an alarming rate in our everyday life. Thus disinfectants are an important component for safeguarding the environment.

Structurally Quaternary ammonium compounds contain a positively charged nitrogen atom which is bonded to four organic groups. These are used as broad spectrum disinfectant.

Quaternary ammonium compounds destroy the cell wall of microbes. The positively charged nitrogen atom binds itself with the cell membrane of the microbes which are negatively charged. This denatures the protein present in the cell of bacteria or fungi impairing their metabolic reaction and finally causes death.

Because different types of combinations are possible many versions of QACs are available commercially. The most commonly found QAC in disinfectants are Benzalkonium chlorides, also known as alkyl dimethyl benzyl ammonium chlorides .Abbreviations for Benzalkonium chloride include BAC, BZK, BKC, and ADBAC.

QAC based products possess superior stability compared to other disinfectants. QACs show the broadest spectrum of efficacy against microbial agents. It shows activity against Bacteria, Viruses, Protozoa, Fungus and Algae.

QACs show good cleaning properties. The main use of QACs are in healthcare sectors.

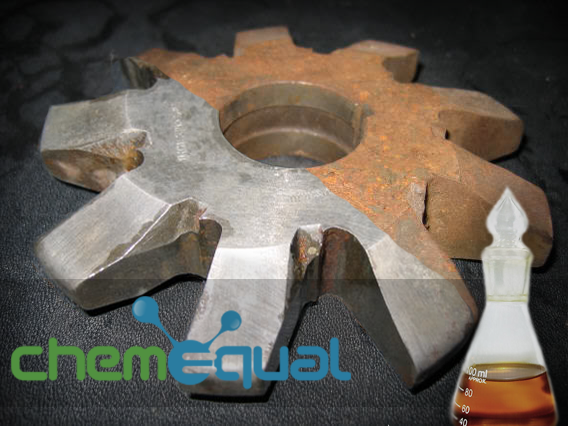

One of the key features of QAC based disinfectants is that they are non corrosive to metal pipes and other surfaces. They can be diluted for easy use and thus cause very little damage to the surface. QAC based products show exceptional material compatibility .

KEY FEATURES

- Economical and easy availability

- Non -damaging on carpets, clothing etc.

- Non corrosive to metal pipes

- Non Toxic

Main Application of Quaternary Disinfectant

- Food Processing Plants-All the instruments and equipments used in food industries need to be sterilized correctly otherwise it would cause alteration in food quality.QAC based products are used extensively to give proper sterilization against all microbial attack.

- Personal Hygiene- QAC for its excellent germicidal activity are used in most hand sanitizers, hand gel etc. It has proven to show 99.99% destruction of common bacteria like Staphylococcus aureus and Escherichia coli for an exposure time of 2 minutes.

- Medical Institutions –For cleaning and disinfecting bathroom surfaces. In many hospital rooms QAC based products are employed in spray fogging for killing airborne and surface bacteria.