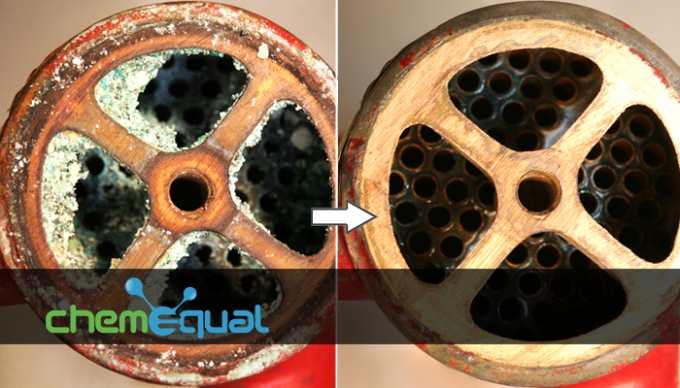

Most metal hot working processes tend to leave a discoloring oxide layer or scale on the surface. Deposition of inorganic impurities, stains, rust and scales from ferrous, cuprous, aluminium and precious metal mostly as oxides hinder with further processes like extrusion, rolling and galvanizing. In jewellery making, soldering and annealing processes leave metal oxide residue that prevent polishing of ornaments. Such impurities are cleaned with the help of diluted solution of acids. The method is called pickling and the workpiece is dipped in a vat of acid solution popularly called “Pickle Liquor”.

Hydrochloric acid replaced the commonly used Sulfuric acid as the pickling liquor because it pickles much faster with minimum base metal loss. The aggressive chloride ion in the acid is the key to high efficiency in the cleaning process. It is used for cleaning metals with an alloy content of 6% or less. An acid inhibitor must be added to the pickling solution to prevent the metal from dissolving or becoming pitted. Such a pickling acid solution is called “Inhibited HCL” and is a blend of Hydrochloric acid solution in water (3% to 10%) and an acid corrosion inhibitor which in itself is a blend of organic compounds that adsorb on the metal surface during pickling.

Rodine 213 is a premium organic blend of keto-amine complex substitutes with non-ionic surfactants, alcohol and solvents especially designed to inhibit attack of hydrochloric acid on metal surfaces during industrial operations like cleaning and pickling. It is effective over a wide range of metal surfaces like Iron & Steel, copper and brass. Rodine 213 is a high foaming formulation with a high efficacy at dispersing grease deposits and is ideal for HCL based pickling liquor solutions especially prior to plating.

It ensures metal surface protection during processes involving elimination of lime deposits from boiler and pipework and from evaporating plants, removal of oxide deposits from iron, steel, brass and copper. Rodine 213 is free from chlorinated hydrocarbons and heavy metals like arsenic and lead. It can be synergized with Hydrochloric acid pickling in stipulated concentrations both by circulation method and by soak and rinse method. Rodine 213’s exceptional strength and commendable heat stability makes it an ideal acid inhibitor during enhancement of the pickling process by pre-heating the equipments with the inhibited acid solution. It also acts as a strong acid fume suppressant.

Its key features can be summarized as follows:

- Modifies metal surface to prevent corrosion

- Easy to use

- Excellent wetting properties for better cleaning

- Effective fume suppression

- Saves Zinc in galvanizing (Plating)

- Reduces metal loss

- Enriches strength of pickling acid bath, and reduces acid consumption

Rodine 213 has widespread industrial application in industries such as Iron & Steel, Power Station, Heavy Engineering Industries, Petrochemical & Refineries, Sugar Processing Industry, Cement, Glass & Ceramic Industries to name a few.