Effective cleaning of equipment in the food processing industry is required to reduce chances for contamination of during preparation, processing, storage & serving. Cleaning prevents attraction of lower life forms like food pathogens, increases equipment life, boosts employee morale and efficiency and accounts for aesthetic considerations of consumers. The primary cleaning agent is water; free from disease producing organisms, toxic metal ions and objectionable taste & odor. But such quality of cleaning water is hard to achieve and chemicals are tailored to meet cleaner specifications based on water composition and operation type.

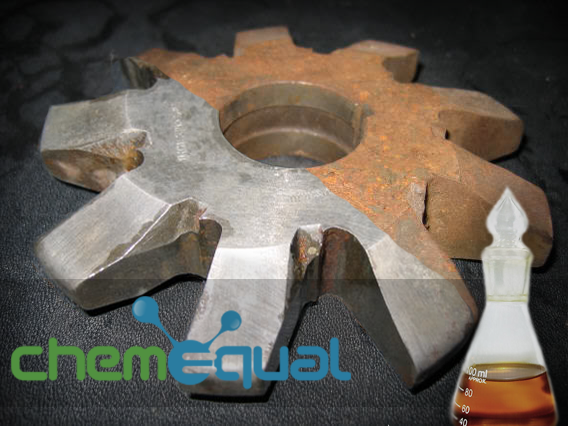

Acid Type Cleaners & Corrosion:

Acid cleaners are used in the food processing industry for milkstone removal and cleaning equipment like broth tanks, ingrediators etc. A wide choice of acid type cleaners for mineral scale removal exist today but organic acids and blends of organic acid type cleaners and chelating agents have found much popularity in recent times. This is because they are much less corrosive than mineral acids and alkaline cleaners. Citric acid and EDTA are frequently used for this purpose owing to a better pH regulation and less aggressive surface action.

Nevertheless, acid cleaning chemicals are corrosive to the base metal and are responsible for corrosion & pitting of surface. Inhibitors for Citric Acid descaling solution are usually applied at very low concentrations (1000-3000 ppm) to provide upto 99.8% corrosion inhibition during acid cleaning processes. Depending on the acid type used, specific corrosion inhibitors are designed to remove scales and deposits from equipment while minimizing base metal loss. They are of mostly polymeric origin and act by forming chelating structures, proving high efficiency as inhibitors in acid chemical cleaning operations.

RODINE 92B is a blend of semi-foaming corrosion inhibitors specifically formulated for preventing corrosion by Citric acid and EDTA based cleaners. It is highly efficient at protecting metal surfaces such as steel and copper alloys commonly associated with equipments in food processing and packaging industry. It has been shown to assist in surface cleaning and descaling actions by acid cleaners without any pitting or corrosion on metal surface.

With respect to the nature of industry where rodine acid inhibitors are used, toxicity issues for inhibitors is of prime concern & exposure to humans due to improper/inadequate rinsing is a possibility. Rodine 92B has been designed for such special applications and contains ingredients generally recognized safe to humans thus suitable for cleaning of food equipments.

Key product features are:

- Modifies metal surface to prevent corrosion

- Excellent wetting properties for better cleaning

- Enhances cleaning efficiency

Rodine 92B is effective upto a temperature of 85°C/185°F and can be applied in all types of food processing, packaging & storage industries as inhibitor for acid cleaning systems.

ChemEqual is a online global chemical marketplace for Acid Inhibitors where Rodine type & its equivalent inhibitors can be found.