Scaling is the precipitation of dissolved impurities in untreated water on the equipment walls. This may lead to buildup of hard water mineral film coats on the surfaces of heat exchangers, cooling towers, boilers & pipelines reducing their efficiency and safe operation of the heating elements. It may result in localized heating along the hot spots leading to tube failures inside pressure boilers and progressive lowering of boiler efficiency by forming an insulative layer. On an average, a 0.4mm thick deposit can reduce boiler’s efficiency by 18.2%.

Scaling is mainly due to calcium and magnesium salts because their solubility is inversely related to the water temperature and silica concentrations. They are mostly classified as limescales most of these being Carbonates and Sulphates. Carbonate scales are granular, porous and dense uniform on the surface while Sulphate scales are harder, brittle and more compact in nature. Another type of scaling is associated with High Silica deposits that are hard, dense and impervious. They are hard to remove owing to inertness against acids. Contrary to these, Iron scale deposits are mostly due to corrosion or iron contamination in water that oxidizes the metal parts of the equipment.

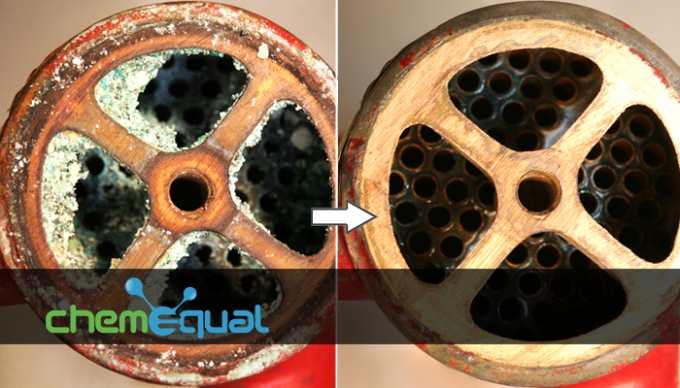

Descaling chemical or is used to remove mineral scales from metal surfaces in contact with hot water, such as in boilers, heat exchangers etc. It is the best alternative to mechanical descaling owing to its ease of use and application methods. It is a high end superior protection to industrial equipments from scaling.

Acid washing is the only satisfactory method for removing mineral scales. Typical descaling chemical compositions include individual or a proportionate blend of mineral acids like Hydrochloric, Sulphamic, Hydrofluoric, Phosphoric, Formic and Citric acids along with applicable corrosion inhibitors and chelants. Descaling Chemical is more of a broader term and it may include application directed products such as Condenser Descalant , Heat Exchanger Descalant, , High Silica Descalant, Silica Scale Remover and Passivation Chemicals.

Liquids are more preferred in the market because of features like

- precise pH correction,

- application over wide boiler pressure range

- multipurpose descaling

- ease of use

Industrial descaling chemicals can be customized for offline descaling, online descaling and immersion descaling based on the nature of scale and system concerned. These chemicals are even suitable for descaling equipments in sensitive industries like pharmaceuticals, oil refineries, power plants, food and beverage industries. The need for chemical cleaning during the lifetime of the equipment has become a recognized fact & should be accepted as a routine maintenance practice. Frequencies of service cleaning depend on the Water Chemistry and Operation conditions.

ChemEqual is a vast online chemical B2B marketplace and various grades, brands of application specific descaling chemicals can be searched here.